PRESSURECALIBRATION

Pressure reading instruments (pressure gauges / pressure transmitter) must be calibrated at regular intervals to check whether they continue to meet their specifications in terms of function and measuring accuracy. Constant use of the measuring devices puts stress on the measuring elements and this can have an influence on the properties. Stress over a long period of time can also lead to changes.

Only with regularly calibrated pressure measuring instruments can truly reliable measurements be made, as it is not possible to predict what influences may have occurred due to ageing, improper use, etc.

The quality assurance standard DIN EN ISO 9001 requires traceable calibration (testing) of all measuring equipment relevant to quality and reliability.

Quote from DIN EN ISO 9001:2015

Where metrological traceability is a requirement or is considered by the organization to be an essential contribution to establishing confidence in the validity of the measurement results, the measuring equipment shall:

- calibrated, verified or both against standards traceable to international or national standards at specified intervals or prior to use; if such standards do not exist, the basis for calibration or verification must be retained as documented information.

- be marked in order to determine their status

- be protected against changes in settings, damage or deterioration, which would invalidate the calibration status and consequently the measurement results.

The organization shall determine whether the validity of previous measurement results has been affected if it is determined that the measuring equipment is unsuitable for its intended use, whereupon the organization shall take appropriate action as necessary.

A test cycle, the type of calibration and the requirements for a calibration laboratory are not specified in this standard. These decisions must be made by each company itself.

The user can calibrate the measuring equipment himself in accordance with this standard if traceable standards (reference devices) are used, if the local conditions and qualified personnel are available.

To calibrate pressure measuring instruments, a constant pressure must be applied (pressurization). Depending on the pressure range and the operating conditions of the test item, air, nitrogen, water or oils are used.

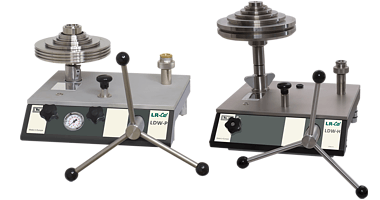

Pressure balances / dead-weight testers and pressure controllers usually have integrated pressure generation.

Both pressure test pumps (portable) and pressure comparison test pumps (stationary) can be used to generate test/calibration pressures.

Absolute pressure

The absolute pressure is the pressure that is related to a vacuum (e.g. outer space). In outer space there is an absolute vacuum (0 Pa abs.). Absolute pressure is usually used for weather values (air pressure). A common abbreviation is "abs".

Accuracy class / quality class

It describes the maximum permissible deviation of the measured values for a measuring device. The accuracy classes for analog dial pressure gauges are specified in DIN EN 837, those for electrical pressure gauges / pressure transmitters in DIN EN 61298-2. The accuracy class is often referred to as "Kl.", "Cl." or % FS.

Adjustment

Measuring devices are set (adjusted) by the manufacturer so that they comply with the specified error limit. Readjustment or readjustment is required if deviations are detected during calibration of the measuring device that are higher/greater than the specified error limits.

Atmospheric air pressure (ambient pressure)

This is the pressure that prevails on the earth's surface. It is created by the weight of the atmosphere (air envelope) above us. It depends on the weather conditions (air pressure) and the height above sea level (sea level). The higher above sea level, the lower the atmospheric pressure, until it reaches zero in space.

Calibration

Determination of the proper functioning of the test specimen and testing of the measured value deviation. The measured values and measured value deviations are documented in a calibration certificate.

Calibration interval

Specification of the time interval between calibrations of a measuring device. Repeated calibrations are also called recalibrations.

DAkkS

DAkkS is the abbreviation for "German Accreditation Body". It has replaced the previous DKD since January 1, 2010 (due to European regulations).

Deviation

The difference between the display/output of the measuring device and the actual value.

Differential pressure

Difference between two measured pressures. The pressure difference upstream and downstream of a filter system can be used, for example, to determine the degree of contamination of the filter.

DKD

DKD is the abbreviation for "Deutscher Kalibrierdienst" (German Calibration Service). It ensures cooperation between accredited calibration laboratories and the PTB (Physikalisch-Technische Bundesanstalt), develops calibration guidelines and the basis for accreditation procedures and promotes the calibration system.

Electrical equipment

Additional electrical equipment is required for the calibration of pressure transmitters. A laboratory power supply unit must be used to provide the required auxiliary power. A precision multimeter is used to display the output signal of the pressure transmitter. The measurement uncertainty of the precision multimeter must be included in the measurement uncertainty analysis.

Gauge pressure

See "Positive overpressure"

Hysteresis

This is the mathematical difference, also known as the reversal margin, between measured values determined for rising and falling series of measured values.

Measurement deviation

Difference between the value measured on the measuring device (test specimen) and the correct value.

Measurement uncertainty

There is no such thing as a 100% accurate measurement on earth. There are always uncertainties and inaccuracies, however small they may be. The measurement uncertainty is a statement about the dispersion of measured values of a measurand around its mean value. It is calculated taking into account many influencing factors, e.g. those of the test specimen, the standard and the ambient conditions.

National standard

The national standards are under the sovereignty of the national metrological institutes (in Germany: PTB - Physikalisch Technische Bundesanstalt). All measurements in the country are traced back to these standards. These are the standards with the highest accuracy.

Negative overpressure

This is the term used to describe a measured pressure that is lower than the current atmospheric air pressure. This pressure is also referred to as "vacuum".

Positive overpressure

This is the term used to describe a measured pressure that is higher than the current atmospheric air pressure. This pressure is also referred to as "gauge pressure".

Pressure

From a physical point of view, pressure is the result of a force F acting vertically on a surface A. Mathematically, pressure is the quotient p = F/A.

The physicist Blaise Pascal discovered that pressure spreads in all directions in liquids and gases at rest. The formula symbol "p" is derived from the Latin word "pressio".

The SI unit for "pressure" is "Pascal" (Pa). 1 Pa = 1 n/m².

Every pressure measurement is actually always a differential pressure measurement. A system pressure is always measured against a reference pressure. This reference pressure can be that of outer space (complete vacuum) or the local ambient air pressure on our planet Earth.

Primary standard

This refers to the immediate direct realization of a unit or the high-precision realization of a unit. The representation of the meter by measuring the length of a laser beam, for example, or the representation of pressure with a pressure balance. With pressure balances, a defined force acts on a precisely defined surface.

PTB - Physikalisch Technische Bundesanstalt

This federal institute is the national metrology institute of the Federal Republic of Germany. It is part of the German Ministry of Economic Affairs. Other leading national metrology institutes include NIST in the USA and NPL in the UK. The PTB is the highest authority in Germany for all questions of correct measurement.

Reference standard

Reference standards are available in accredited calibration laboratories and are used to calibrate the test equipment used in a country. These reference standards are regularly compared with the national standards. This ensures a reliable metrological infrastructure in the country.

Repeatability

The difference between two measured values that were recorded under the same conditions but at different times is called repeatability (also known as reproducibility). Repeatability provides information about the long-term reliability of a measuring device. It is included in the calculation of measurement uncertainties.

Reproducibility

An uninterrupted chain of calibrations that extends to national or international standards is referred to as traceability.

Working standard/reference instrument --> Primary standard --> DAkkS --> PTB

Each step further away from the national standard increases the measurement uncertainty (less accurate measurements).

Test item

The test item is the measuring device that is to be calibrated. It is often also referred to as the calibration item or unit under test UUT.

UUT - Unit under test

See "Test item".

Working standard

They are used internally, for example, as a reference device for the calibration of measuring equipment. They must be checked regularly with a reference standard from an accredited calibration laboratory.

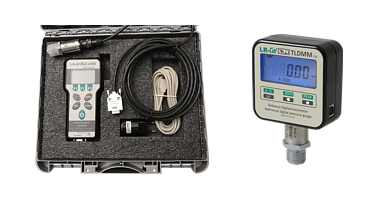

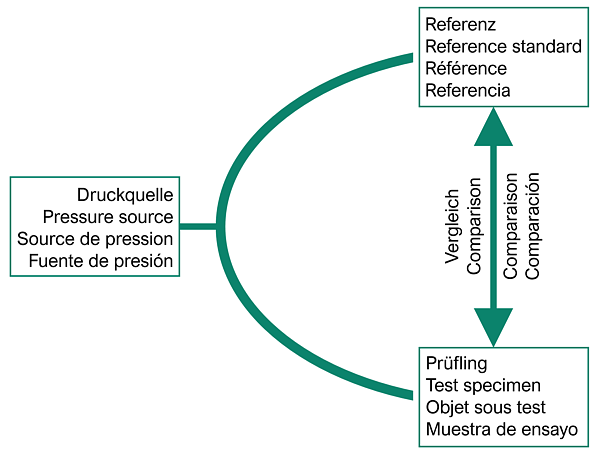

For a pressure calibration you usually need a calibration pressure source as well as a sufficiently accurate reference pressure measuring instrument (pressure calibrator, precision manometer, process calibrator). When selecting the reference measuring instrument, please note that the accuracy specification usually refers to the measuring range span ("f.s." = "full scale" = from the final value). This must be taken into account when selecting the required measuring ranges for the reference instruments. For pressure balances / piston manometers, the accuracy specification "o.r." (= "of reading") refers to the measured value.

Reference instruments must themselves be regularly checked for their measuring accuracy and certified. We recommend having this recalibration carried out at annual intervals, deadweight tester / pressure balances every five years.

Recommendation for performing a pressure calibration

Calibration object (test specimen):

- if possible, calibrate the entire measuring chain.

- take into account the prescribed installation position.

- distribute measuring points evenly over the calibration range. The zero point is usually also a measuring point.

- check in advance for calibration capability.

Calibration procedure:

- consider environmental conditions

- select suitable calibration procedure

- For analog pointer instruments as calibration object:

Setting the measuring points according to the display of the calibration object.

Reference meter (standard):

- Measurement accuracy four times better than that of the calibration object

- Traceability to National or International Standards.

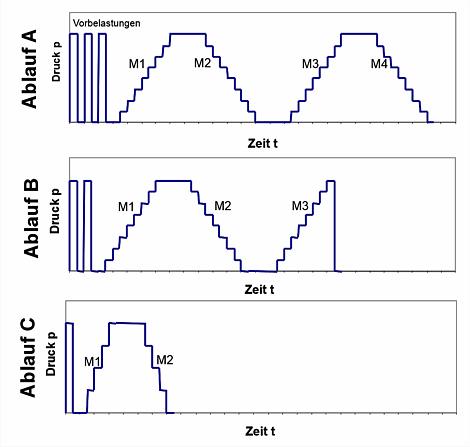

Recommended calibration procedures:

[Ablauf = Procedure | Druck = Pressure]

Accuracy (grade) of the calibration object <0.1% FS:

Procedure A

- 3 preloads with measuring range end value of the test specimen

- 9 test points (including zero point)

- 2 up and 2 down rows

Accuracy (grade) of the calibration object 0.1...0.6% FS:

Procedure B

- 2 preloads with measuring range end value of the test specimen

- 9 test points (including zero point

- 2 up and 1 down row

Accuracy (grade) of the calibration object > 0.6% FS:

Procedure C

- 1 preload with measuring range end value of the test specimen

- 5 test points (including zero point)

- 1 up and 1 down row

Notes:

Upward row: with increasing pressure

Downward row: with falling pressure

For pressure gauges with preload, recognizable by a pointer stop pin at the zero point, the zero point is NOT a test point.