Pressure gaugeswith electric contacts

-

Analog pointer pressure gauges with electrical contact device:

- with magnetic spring contact(s), or

- with inductive contact(s) (also Ex), or

- with electronic contact(s), e.g. for PLC control -

Dry or housing filled with damping fluid

-

Bourdon tube measuring system made of brass or stainless steel

Diaphragm measuring system made of steel or stainless steel -

For gaseous or liquid media

DS 100 with bourdon tube

Wetted parts: stainless steel

Safety execution SOLID FRONT

DS 160 with bourdon tube

Wetted parts: stainless steel

Safety execution SOLID FRONT

DS 100 + DS 160 with bourdon tube

Wetted parts:

brass or stainless steel

SF6 Gas Monitoring

(no electronic contacts available)

DS 63 with bourdon tube

Wetted parts: stainless steel

Safety execution SOLID FRONT

(no electronic contacts available)

DS 100 + DS 160 with diaphragm

Differential pressure

Wetted parts: stainless steel

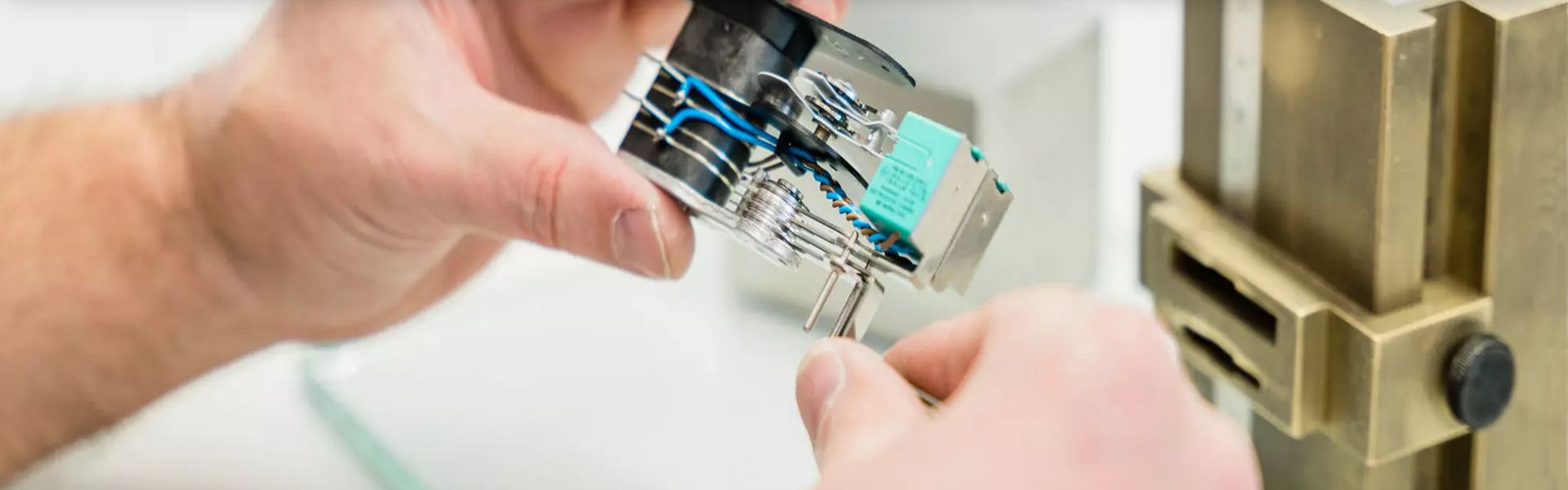

Contact pressure gauges are used in many areas where the process pressure must be indicated on site and circuits must be switched at the same time. They are also referred to as limit switches, as they trigger an alarm when the pressure exceeds or falls below the set measured value. Contact pressure gauges are usually equipped with switching contacts, which are usually adjustable by the user. Apart from the different measuring systems (Bourdon tube or diaphragm), there are three different types of contact pressure gauges, which differ in their switching contact type: Magnetic spring, inductive and electronic contacts.

Contact pressure gauges are used in many areas where the process pressure must be indicated on site and circuits must be switched at the same time. They are also referred to as limit switches, as they trigger an alarm when the pressure exceeds or falls below the set measured value. Contact pressure gauges are usually equipped with switching contacts, which are usually adjustable by the user. Apart from the different measuring systems (Bourdon tube or diaphragm), there are three different types of contact pressure gauges, which differ in their switching contact type: Magnetic spring, inductive and electronic contacts.

Magnetic spring contacts

Contact pressure gauges with magnetic spring contact can be installed in almost all operating conditions and are based on a screwable permanent magnet at the set pointer. As a result, the contacts are largely protected from the effects of arcing. The snap-action characteristic of the contact system provides a leading signal to the movement of the pointer. If the magnetic snap contact pressure gauge is used correctly, it will function properly for many years, especially in the case of contact pressure gauges filled with damping fluid. Magnetic spring contacts are less expensive than inductive and electronic contacts.

Inductive contacts

Contact pressure gauges with inductive contacts are mainly used in hazardous environments of danger zone 1 and 2 as well as with high switching frequency. The inductive contacts operate without contact, are wear-free and have no feedback effect on the measuring mechanism of the contact manometer. They are insensitive to aggressive environments and can be used universally even with filled contact manometers.

Electronic contacts

Contact pressure gauges with electronic contacts can directly switch low powers, such as are common in PLCs (programmable logic controllers). The electronic contacts also operate without contact, are wear-free and have no feedback effect on the measuring mechanism of the contact manometer.